Case Studies

Home | Case Studies |Chevron 20M Reel

CASE STUDY 5:

Chevron 20M Reel

Project Specification

HCS was commissioned to deliver a unique and bespoke project for a client to enable them to deploy and retrieve 2,300m of supporting umbilical.

The specification of delivery included:

- Hydraulic Winch c/w integrated HPU and top spooler system.

- NEC 505, Zone 1 hazardous area.

- Operating temperature range -20°C to +50°C.

- 77 tonne, DNV certified, 2-piece self-supporting umbilical winch:

- 64.7-tonne hydraulic winch (this included umbilical weight).

- 12.3-tonne top spooler system.

- Winch: 7,500mm (l) x 5,000mm (w) x 4,600mm (h).

- Spooler: 8,750mm (l) x 2,000mm (w) x 2,650mm (h).

- Hydraulically driven c/w electric controls:

- Full proportional speed control.

- Hydraulic dynamic braking.

- Back tension with proportional tension setting.

- 2off 45kW motors.

- Electrical control panel, starter panel, local and remote-control panels.

- Drive system c/w safety interlocks to prevent operator injury.

- It was designed to accommodate 3,200m of Ø94mm umbilical.

- Line speed 15m/min at the inner layer.

- It was designed for a maximum line pull of 133kN.

- We introduced an integrated weight indicator to monitor the tension in the umbilical, providing a constant visual indication of the line tension. Additionally, both audible and visual alarms fitted in the event of an over-tension situation occurring.

- Top spooler system integrated into the central drive system.

Our Delivery

The experience, strength and skill at HCS throughout the last 20 years for designing umbilical reelers proved that we could comfortably achieve the clients’ brief.

With a wealth of experience in various systems, we have ambitiously developed innovative engineering solutions to overcome client and industry challenges.

Working on this project presented several challenges for HCS, and we have had to consider each one individually. We had to call upon our previous experience to deliver a fully compliant system that was fit for purpose successfully.

Several challenges HCS faced included;

- We designed the first 20K system of its kind, showcasing our excellence in engineering.

- We were tasked to build a system that would be capable of two modes of operation.

- The equipment had to be self-supported (using an A-Frame / LARS system).

- The equipment had to be lamped (via the moonpool).

- During its first campaign, the system would only be operated at 2,440m (4th layer in self-supported mode only).

- A top spooler system had to be designed for deploying and retrieving the umbilical c/w power override. A passive tilting sheave needed to be introduced to accommodate the inner to outer layers on the winch drum.

The Result

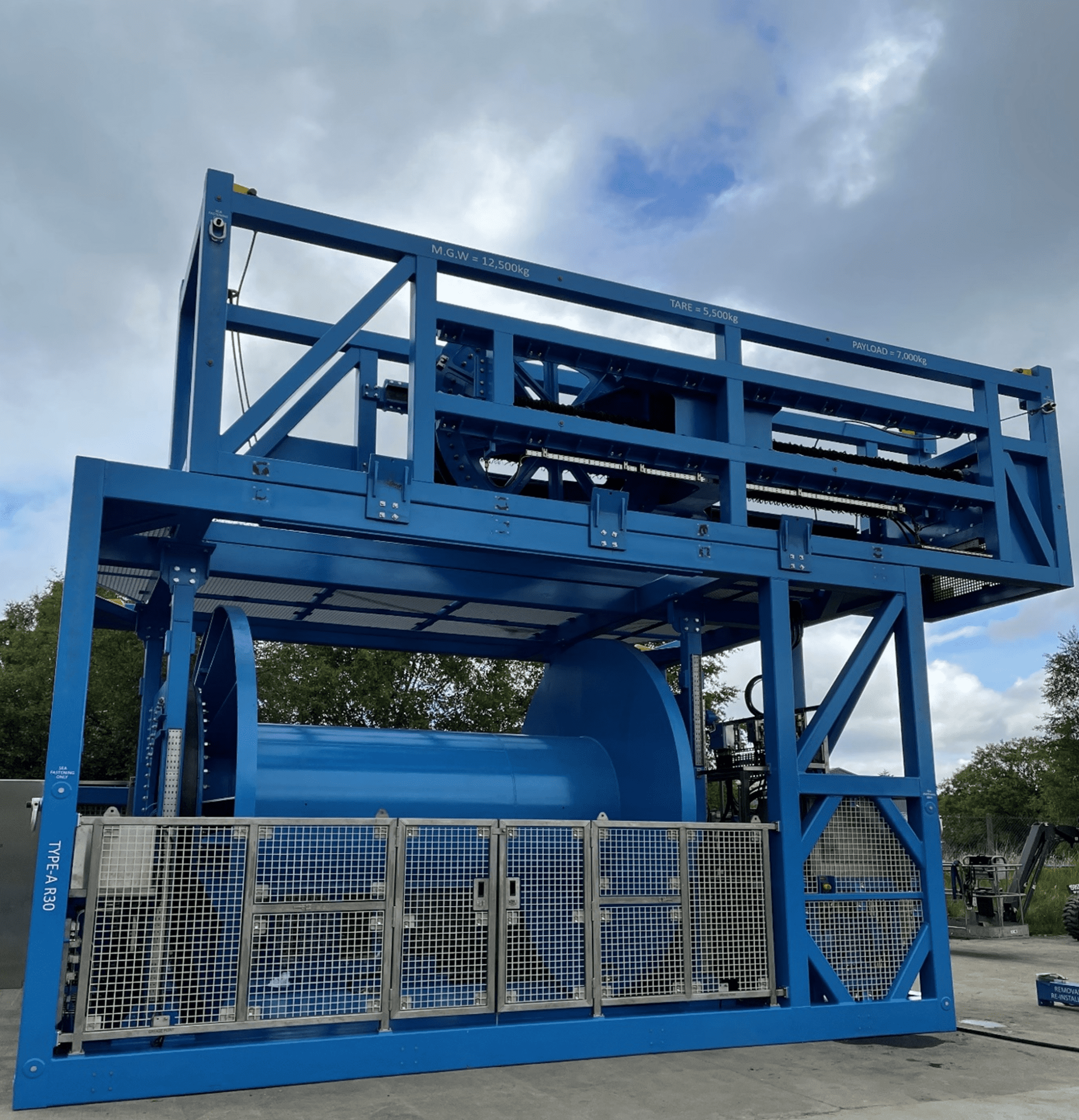

HCS proudly showcased our capabilities in innovative bespoke engineering, project management, and exceptional quality to deliver this 7m high hydraulic winch and top spooler. This truly was a first of its kind project.

It was an especially remarkable achievement for HCS because we overcame several challenges encountered throughout the project’s design phase.

After successful completion of the FAT, this system was delivered to our client in June 2021.