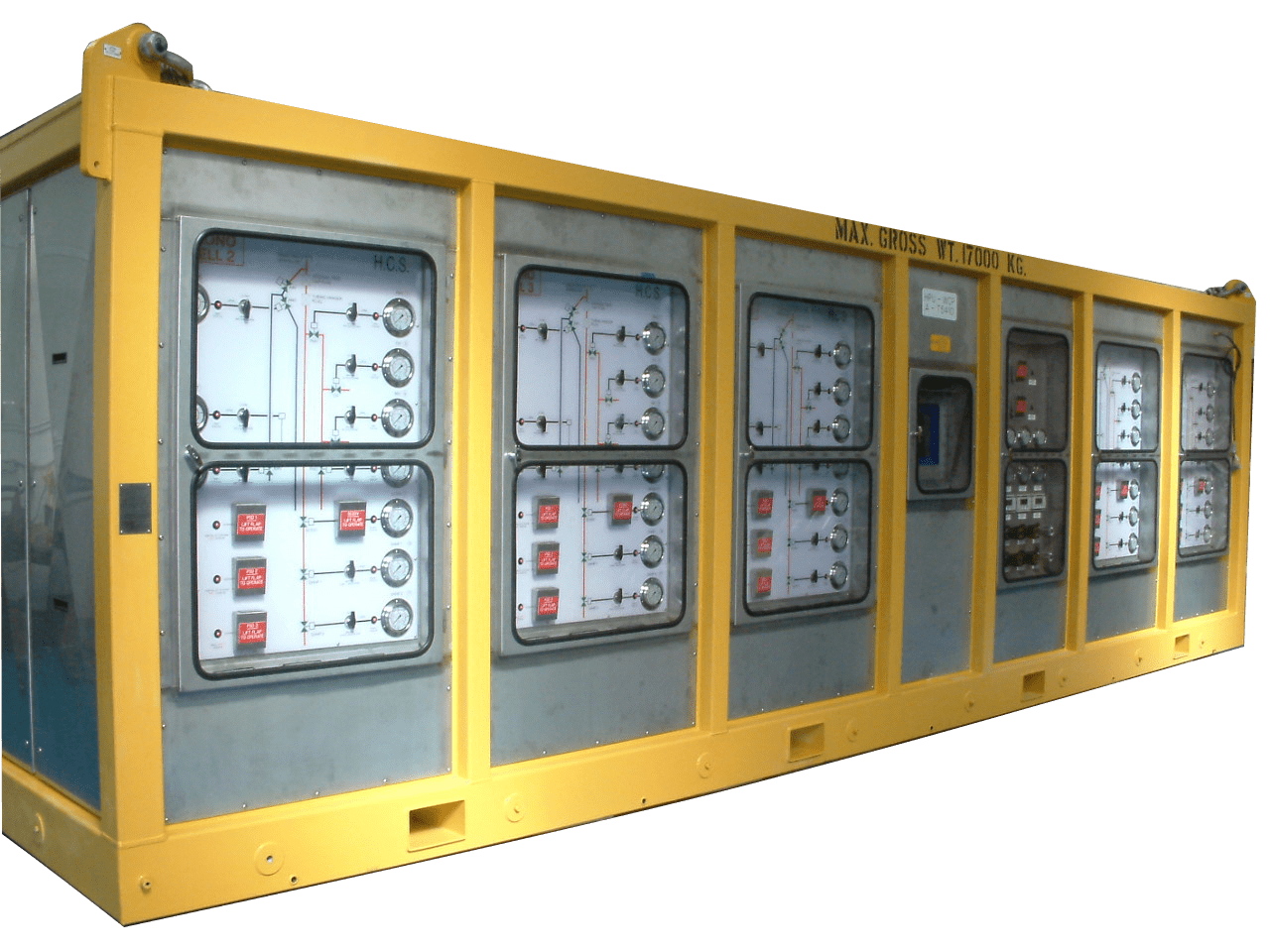

PRODUCTION CONTROL SYSTEMS:

PRODUCTION HPU

HCS has experience in the design and manufacture of simple panels as well as large walk-through units. Bespoke low, medium or high pressure HPUs can be designed to any; footprint, height and weight. Multiple well-head slots and client specific functional controls can also be engineered to suit any work scope.

- Choice of pneumatic or electric pressure generation.

- Customisation of ESD to interface with client’s control philosophy

- Operating system can be direct, manual valve or electro hydraulic (EH) controlled via PLC/HMI

- Accumulation within separate ventilated compartment if required

- Full emergency stop system

- Pressurised container, suitable for use in hazardous areas can be integrated

- Future proofing by adding spare slots

- Fire detection system

- Integrated air conditioning units

- Pressure Test / Flush/ FAT Testing

- Training provision for client’s personnel

- Maintenance and technical support

- Manpower installation and commissioning

- All manufacturing processes are accredited by Lloyds ISO 19001

- All stages of fabrication and assembly can be carried out on site thereby ensuring full control of quality and production processes

- Production welding can comply with any specific quality or industry standards.

- Experienced using conventional and exotic materials including; inconel 625, 6Mo, duplex, super duplex and hastelloy C276

- CE compliant (including ATEX and machinery directives)

- IECEx certification if required

- Steel frames can be certified to DNV GL-ST-E271

- NORSOK compliance