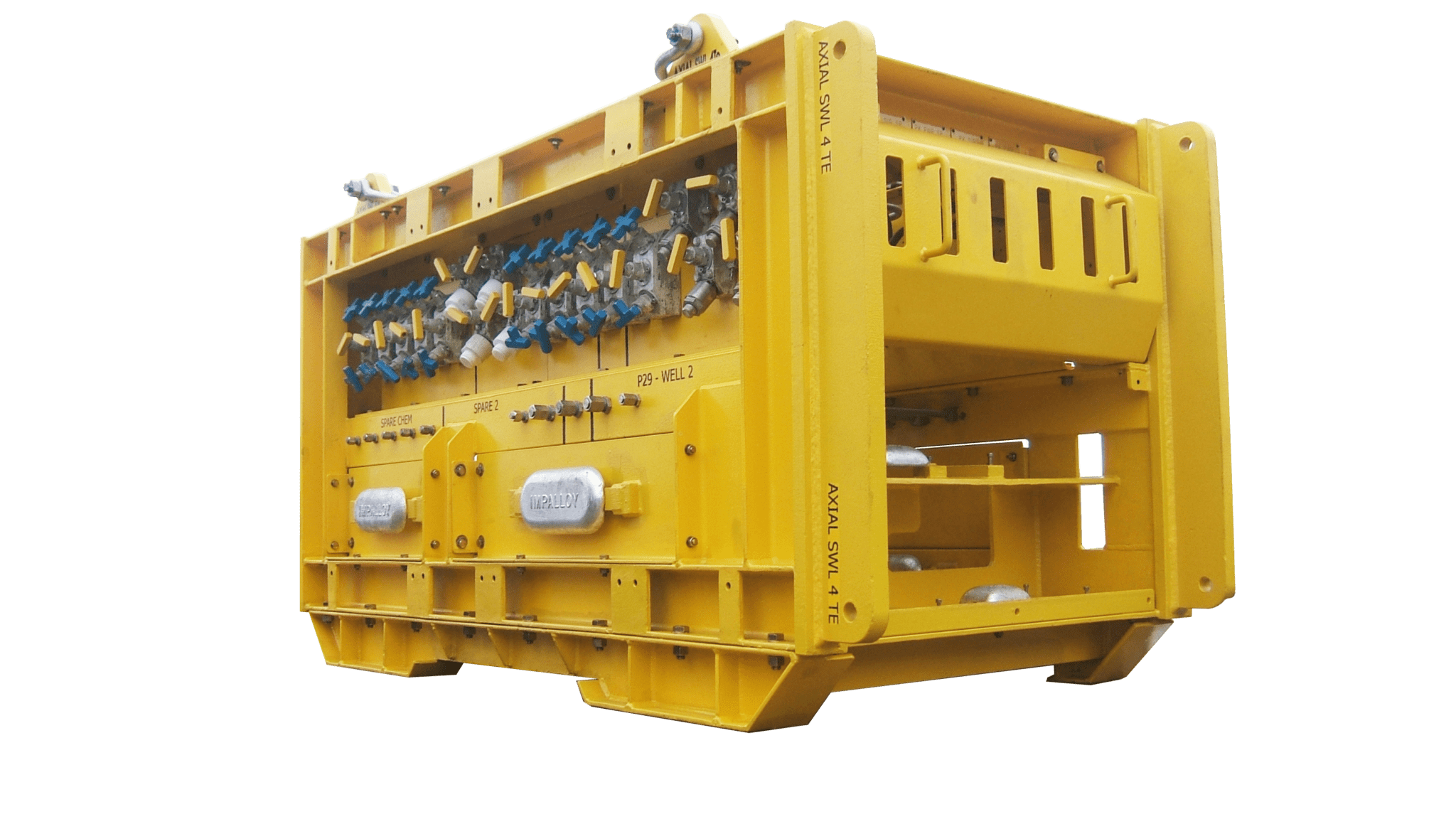

SUBSEA ASSEMBLIES:

SDU/UTA

HCS has extensive manufacturing capability to undertake the design and manufacture of SDU / UTA equipment. Our competitive strengths include; our quality and safety credentials, highly skilled and experienced technical teams and our ability to offer in-house testing and SIT services.

- Multiple outputs can be customised to number of trees in work scope

- Internals can be manufactured from stainless steel or duplex dependent of fluid selection and test procedures

- Optional subsea valves

- Direct output can be to singular coupler or complete stabplate/MQC plate

- EDU can be fitted internally within structure or recessed on top for easy access

- Carbon steel structure can be painted to client spec

- Pressure Test and Flush

- SIT if required

- Load Test to client specification

- CompEx approved electrical testing

- Maintenance and technical support

- All manufacturing processes are accredited by Lloyds ISO 9001/OSHAS 18001:2007

- All stages of fabrication and assembly can be carried out on site thereby ensuring full control of quality and production processes

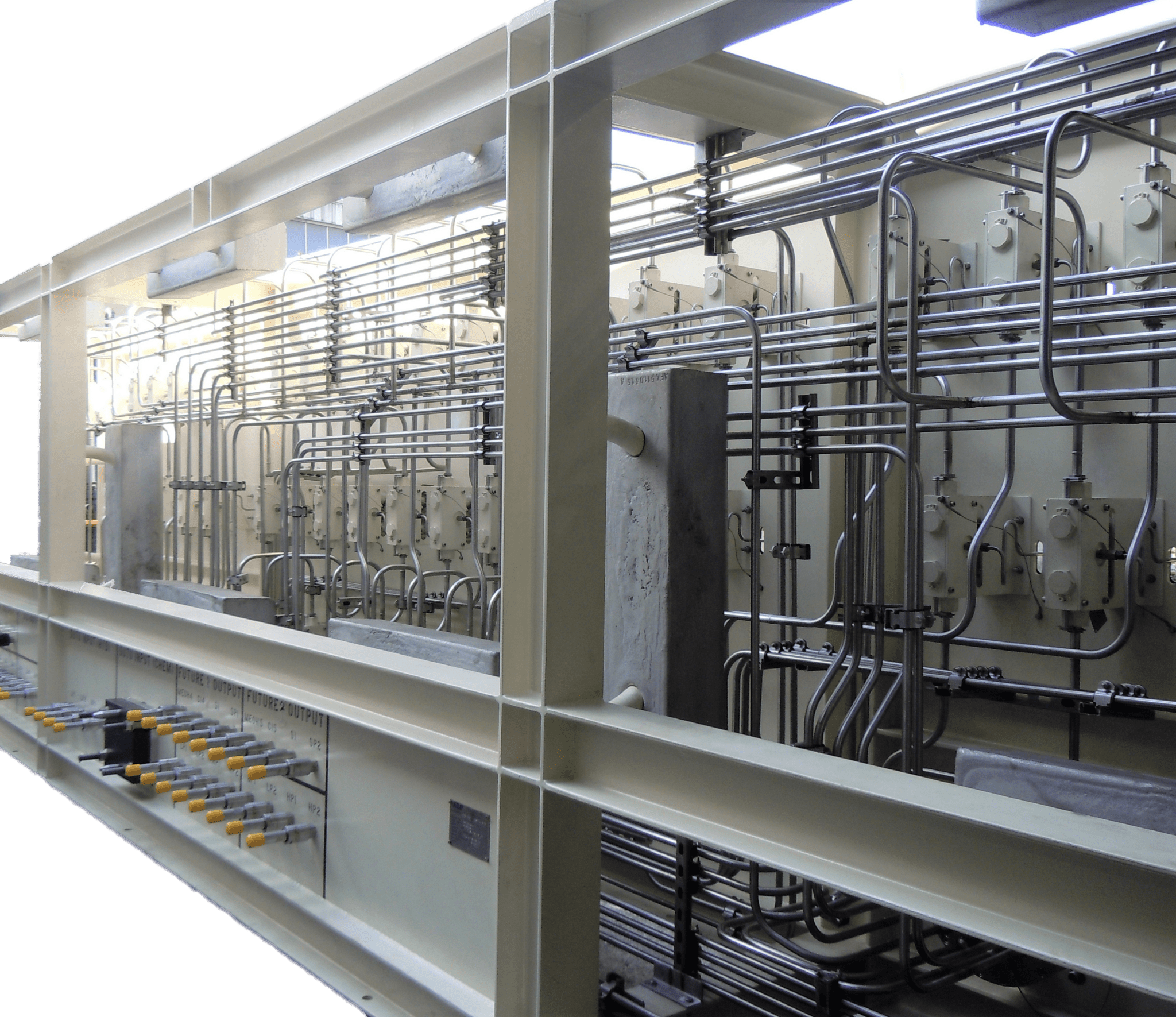

- Basic structures have an input which could be welded directly to the umbilical or connected via bulkhead plate on the umbilical side

- Production welding can comply with any specific quality or industry standards.

- All tubing within the SDU is fully welded using the orbital welding proses which can be either autogenous or wire feed welding

- 100% of welds undergo radiography and DPI giving full traceability

- CE compliant (including ATEX and machinery directives)